Description

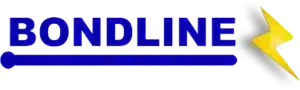

Moisture Barrier Bags are designed for the safe packing of SMDs; protecting them from moisture and static damage.

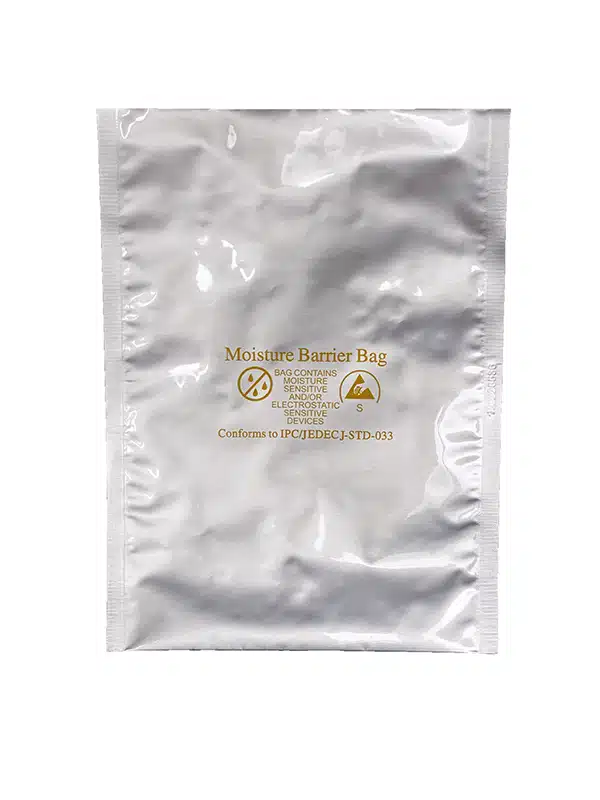

Moisture Barrier Bags protect electronic components and devices from moisture and static damage during storage and transportation. Dry devices are placed inside the Moisture Barrier Bag and the moisture laden air is evacuated. These bags are suitable for storing static sensitive devices and parts in humid environments. Moisture Barrier Bags are Jedec compliant; enabling you to safely transport Jedec Trays. Each bag has a layer of aluminium that blocks the moisture. Moisture Barrier Bags should be used with a Humidity Indicator Card and Desiccant. Humidity Indicator Cards report the effectiveness of the package upon device use. Desiccant filled pouches scavenge the remaining moisture from the bag’s interior which is entrapped by the desiccant.

The Moisture Barrier Bags are opaque and light-tight ensuring the contents cannot be seen from the outside; adding a layer of operational security. They are suitable for packing electronic products which are sensitive to moisture and static. The 4mil puncture-resistant and moisture-proof packaging has a flexible structure and is suitable for vacuum-sealing. Supplied in packs of 100 pieces. Wide range of standard sizes in stock to select from, with custom sizes and thicknesses on request.

Before each use, ensure that there are no wrinkles or surface scratch, damage or pin holes.

Key Features of Moisture Barrier Bags:

- Protects electronic components and devices from moisture and static damage

- Suitable for storing static sensitive devices in humid environments

- Supplied in packs of 100 pieces

- Jedec compliant, allowing you to safely transport Jedec Trays

- Manufactured with a layer of aluminium that blocks the moisture

- Bags are heat-sealable with ‘Faraday Cage‘ protection

- Vacuum-sealable

- Light-tight and opaque

- Puncture-resistant

- 4mil thick as standard

- Printed with a yellow ESD symbol on packaging

- Recommended temperature for welding is 150-200°C

- Construction: Static dissipative polyester, aluminium shield, static dissipative polyethylene

- Suitable for packing SMDs, PCBs, integrated circuits

- Fully stocked range of sizes available

- Bespoke sizes and thicknesses available on request

Specifications:

- Surface Resistivity / Resistance: >10^(6) <10^(11) ohms/sq. >10^(6)<10^(11) ohms/sq.

- Static Shielding: 30 volts STM11.31

- Static Shielding: <50 nj STM11.31.2006

- Static Decay: <2 seconds

- Charge Retention: <100 volts

- Puncture Strength: ≥10.2kg

- Burst Strength: 146kg/cm^(2)

- Snap Power: ≥3.7kg

- Elongation Rate at Break: ≥3.3kg

- Tear Strength: ≥0.6kg

- Peel Strength: ≥0.5kg

- Heat Seal Strength: ≥3.7kg

- Thickness: 100micron (4 mils) +/- 10%

- OTR: ≤1.4cm3/(m2.24h.0.1MPa) ASTM D3985

- Shelf Life: ≥3 years

- WVTR: ≤0.0310 g/m2 (0.002 g/100 in2) in 24 hours at 40°C after flex testing per condition “E” ASTM F 392. (ASTM F 1249)

ESD Standards & Regulations:

|

IPC / JEDEC J-STD-033, ANSI/ESD S20.20, STM11.31 2006, EIA541, MIL-B-81705C Type 1, IEC 61340-5-1, FTMS101, MTH2065, GB/T 1040, ISO 527-2: , ASTM D639-03, ASTM D-638, GB/T 16578-96, ASTM D1938-02, ASTM D-1876-72. |

| REACH compliant | |

| RoHS compliant | |

| European Conformity |

Additional Information

Bespoke sizes, thickness, printing and packaging solutions can be manufactured on request. For a large volume qty or a bespoke quotation, please contact us.

For further help and guidance on choosing the right ESD bag, please refer to our ESD Bag Selection Guide.

To view our full range of ESD Bags, see here – ESD Bags | Bondline Electronics.