Description

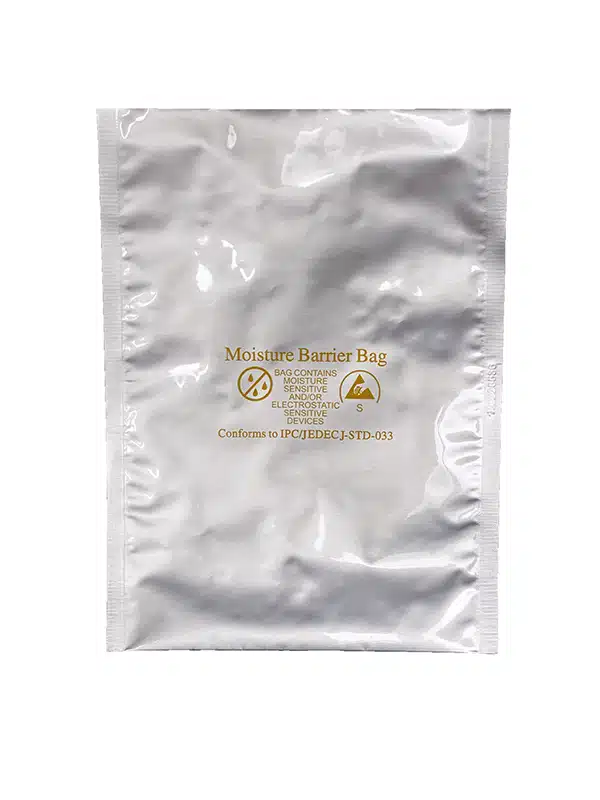

Desiccant bags are used for protecting packaging and enclosure contents that are susceptible to damage from moisture. Desiccant bags are a drying agent which attract moisture from the atmosphere. The bags contain natural bentonite clay with no additives and are filled with high active agents; offering the ideal solution for protecting moisture-sensitive goods such as printed circuit boards, integrated circuits and SMDs. The desiccant’s absorption capacity can be as high as 30% of its weight. It absorbs and holds particles of water to itself. For maximum effectiveness, desiccants should be used within a closed/sealed moisture barrier bag. The activated clay is environmentally friendly as it is chemically inert and non-toxic for metal or any material which makes it safe to handle and therefore can be easily disposed of. The clay desiccants are packed in Cleanroom compatible, sulphur-free Tyvek bags for use in the electronic industry. 1 unit = 35grams of clay.

The addition of Humidity Indicator Cards allow a visual check of the humidity levels inside enclosures or packaged items. This also gives a fast evaluation of the desiccant’s performance.

The desiccant clay is an effective and inexpensive static desiccant, which is enclosed in Tyvek, it will absorb moisture from sealed spaces to prevent corrosion and mould growth. It is widely used in military industries, precision instrument machinery electric and metal products, pharmaceutical, clothing and foodstuff leather.

Bentonite clay is a naturally occurring mineral as opposed to a chemically synthesised absorbent. Therefore it is more economical than silica gel or molecular sieves. The performance curve exceeds both industry standards, and the silica gel performance curve for these same specifications.

At 20% RH, the activated clay bags will absorb 50% more moisture than required by industry standards, whereas silica gel will only absorb 3.5% more moisture than industry standards require. The packaging is sealed inside a waterproof and moisture vapour-proof container with the inclusion of a desiccant to prevent rust, mildew or corrosion damage. In Method II packaging, the package is maintained at a safe humidity below 40% RH during the normal storage period of 18 months to 2 years.

Key Features:

- For moisture damage prevention

- Activated clay is environmentally friendly, chemically inert and non-toxic

- Desiccant bags are to be used in ESD packaging of moisture sensitive devices – according to MILD3464E and JEDEC J-STD-033 standards

- The clay desiccants are packed in Cleanroom compatible, sulphur-free Tyvek bags for use in the electronics industry

- Low dust tear proof bags or dust free paper bags are available

- 1 unit = approx 35 grams of clay

- Conforms to IEC-61340-5-1, DIN55473 and KMIL-D3464E standards

- RoHS and REACH compliant

- CE approved

Options:

- TYDES2: Two unit (Pack of 250)

- TYDES1: One unit (Pack of 500)

- TYDES05: Half unit (Pack of 1000)

Specification: