Electronic components containing transistors or integrated circuits should be regarded as susceptible to electrostatic discharge (ESD). So what is electrostatic discharge? Why should you keep your workplace protected from ESD? Putting together an ESD Control Plan in place can help your workplace avoid ESD damage. When the charge of an object differs from another, ESD damage can occur. To reduce the possibility of ESD damage, it is often necessary to equalise the charges between a system unit. With charge equalisation, the operator, the device and the surface it is being handled on all have the same charge. Taking basic precautions and handling electronic components the right way can help protect static sensitive electronic components. This article covers how ESD is generated, ESD basics, the common sources of ESD, and how you can keep your workplace protected from electrostatic discharge.

How Is ESD Generated?

With the widespread use of electronic devices comes the issue of ESD. So what can cause electrostatic discharge? ESD occurs when two electrically charged surfaces or objects come into contact with one another and static electricity is discharged as a result. An example of this is when the human body makes contact with an electronic component.

Everyday occurrences can generate a static charge. Simple actions such as walking across a carpet or even working on a bench can produce charges. The human body can generate thousands of volts. These volts can be transferred to any electronic device that makes contact with the human body. As a result of this contact, static charge can build-up between the device and human body and discharge onto the electronic device. This can cause the device to malfunction or its integrated circuits to be damaged. The average person is not even capable of sensing static charges, not unless the charge reaches around 3,000 volts. However, for static sensitive devices, a charge of as little as 10 volts can cause severe damage to them.

What Causes ESD Damage?

Typically, ESD damage is the result of one of three events. Among them are discharged onto the device, ESD from the device and field-induced discharges. When any of these three events occur, it can inflict damage on an electrostatic discharge sensitive (ESDS) device. If the device gets damaged, it may be due to its inability to withstand the volts. It may also be because it was not able to dissipate the energy from the discharge.

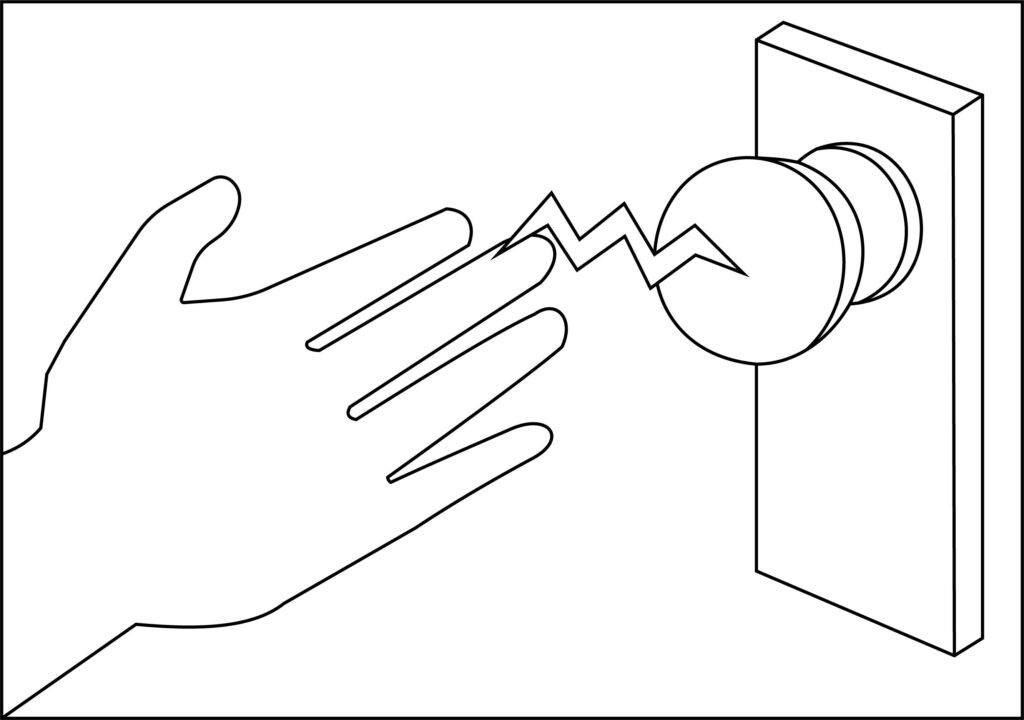

Discharge onto the device

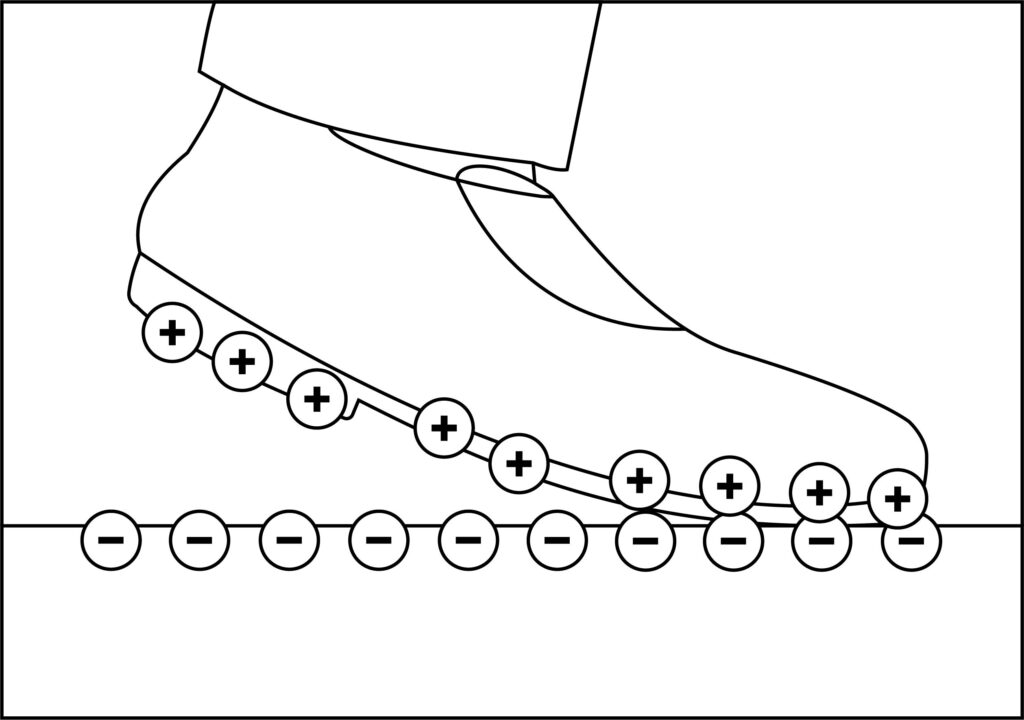

This is one of the events that can cause ESD damage. It occurs if any charged conductors discharge, and the charge is transferred directly to a device. Note that the human body is also considered a charged conductor and can transfer electrostatic charge to a device. As mentioned, everyday occurrences can generate charges. An individual accumulates electrostatic charges whenever they walk across a floor. Once there’s a build-up of static charge, simply touching the device or making contact with it through any part of the body can transfer the charge to the ESDS. Likewise, any other charged conductor can discharge and cause damage to the ESDS.

ESD from the device

This is another ESD event that can cause damage to electronics. Also referred to as the charged device model (CDM), this is when the device itself directly transfers its charge to a conductor. The ESDS may accumulate charges through various production or assembly processes. An example of this is when the device is being handled or assembled. It may also collect charges when it comes into contact—and then separates—with work surfaces, machines or packaging materials. A device typically accumulates charges by moving across surfaces. For instance, sliding on a feeder may result in the accumulation of charges. Then, it can discharge once it comes into contact with a conductor or conductive surface.

Field-induced

This event also referred to as field induction or the field induce charged board model (FICBM), is when electrostatic charges are transferred directly or indirectly to the ESDS, causing damage to it. As soon as an object acquires an electrostatic charge, an electrostatic field occurs. Suppose the ESDS is placed within this electrostatic field and subsequently grounded while still being within the area. Then, a CDM event occurs as the device discharges. If the item is grounded after being taken away from the field, another CDM event occurs.

Here are some key examples to takeaway:

- An operator walking across a waxed floor, with the absence of ESD foot grounders, can build-up a static charge. This accumulation of static charge can discharge onto an item that the operator is handling (i.e. a static sensitive device), causing ESD damage to the device.

- Handling static sensitive components without being connected to Earth via a grounding system can put your components at risk to ESD damage.

- Components placed on conveyor belts are susceptible to ESD damage. This is because equipment such as conveyor belts can generate static charges which can be discharged onto the electrical device.

Common Sources of ESD Damage

The typical work environment has many different sources of static electricity. It’s important to learn about these different sources so that you can avoid them or put effective countermeasures in place to keep your static sensitive electronic components and devices protected from ESD.

Here are some specific examples and scenarios of where static charges can come from:

- A typical scotch tape dispenser: the tape itself builds up a static charge coming off the roll and dispenser

- Placing static sensitive components on work surfaces that are not ESD-safe

- Waxed surfaces or those made from plastic

- Waxed floors, vinyl tiled floors

- Using plastic bags for storing devices

- Using packaging materials that have lost their anti-static properties over time

- Typical office supplies made of insulating materials such as a scotch tape dispenser

- Plastic water bottles on the workstation

- Wearing ordinary coats or smocks and footwear

- Not correctly sealing up anti-static bags or conductive containers and then transporting them to another location

Here are some examples of typical electrostatic voltages:

- Walking across a carpet can generate a static charge of 1,500 to 35,000 volts

- Walking over an untreated vinyl floor can generate a static charge of 250 to 12,500 volts

- A vinyl envelope used for work instructions can generate a static charge of 600 to 7,000 volts

- A worker at a bench can generate a static charge of 700 to 6,000 volts

- Picking up a common plastic bag from a bench can generate a static charge of 1,200 to 20,000 volts

A person can generate thousands of volts just from doing everyday actives such as walking. Even different types of equipment and materials can also generate charges that can cause ESD damage to a static sensitive component. Examples of this include: trolleys, conveyors and automated equipment for handling and assembling products.

The amount of static electricity generated generally varies. This is based on materials, area of contact, friction, and the relative humidity of the environment. At a lower relative humidity, the charge generation will increase as the environment is drier. Common plastics typically create the greatest static charges.

Often at times, charged insulators can generate an ESD event even without coming into contact with the device itself. It does so through an electrostatic field.

ESD Basics For Your ESD Control Program

To protect your Electrostatic Protected Area (EPA) from ESD, it is important to follow the following ESD basics for your ESD control program per IEC 61340-5-1:

- Only handle unpackaged static sensitive electronic components or devices in the static controlled area when grounded

- Only allow trained people, visitors, or accompanied people in the Electrostatic Protected Area (EPA)

- All conductors, including people, must be grounded in the Electrostatic Protected Area (EPA)

- ESD wrist straps must either be tested at least daily or used with a continuous monitor

- ESD footwear must be tested at least daily if used in the EPA

- Conduct a visual check of the grounding cords to see if they are connected

- ESD wrist straps must be worn snugly around the wrist for good connection

- Keep the foot grounder grounding tab in the shoe and ensure ESD garments cover all clothing on the person’s body

- The work area must be kept clean and clear of all non-essential insulators (i.e. plastic bottles, loose sheets of paper, etc.), or neutralise essential insulators with ionisers with the airflow directed towards the workstation.

- ESD protective packaging (i.e. static shielding bags) should be used for the storage or transportation of static sensitive electronic components and devices outside the static controlled area

How To Prevent ESD In The EPA

An effective way to prevent damage to static sensitive electronic components and devices is by using ESD control equipment. ESD mats, for instance, help mitigate ESD by eliminating static electricity by dissipating the charge to ground. Grounding straps, on the other hand, provide a reliable path to Earth and prevent static charge accumulation. When choosing to purchase ESD control equipment, you should check to see if the equipment is qualified and compliant according to IEC-61340-5-1 International Standard. Best practices should also be implemented, such as not removing static sensitive electronic components from their containers until they can be safely handled again at ESD-safe workstations. Designating a room where static can be effectively controlled should also be implemented alongside using ESD control equipment. This will allow for an ESD safe working area when handling, assembling and manufacturing your electronics. Establishing an Electrostatic Protected Area is simple – take a look at our guide here.

Selecting the right ESD products can be overwhelming, especially if you’re new to ESD control. To help you out, here is our list of the top 6 products we recommend when starting out in ESD control.

| ESD Mat |  |

Bonding Plug |  |

| ESD Wrist Strap |  |

Resealable Static Shielding Bag |  |

| ESD Cord |  |

Surface Resistivity Meter |  |

EPA Inspection

Now that you understand what the common sources of ESD damage are, you should look to review your EPA and current ESD control practices with an ESD audit. To check to see whether your ESD Control Programme meets the IEC 61340-5-1 Standard, an ESD control survey can be carried out at your Electrostatic Protected Area.

With an EPA inspection, businesses can check to see whether all the ESD control products and practices are within compliance to the IEC 61340-5-1 International Standard as well as identify any improvements or changes to make.

Make Your Workplace ESD-Safe

Creating an ESD-safe workplace entails being mindful of the common sources of ESD damage and using the appropriate ESD control equipment to mitigate static charge. Bondline offers a wide variety of static control products to help you achieve this. Browse our catalogue here.

Contact Us

We’re always happy to help! Please call us today on 01793 511000 or email us at sales@bondline.co.uk for ESD advice and support.