A Trusted UK Supplier Of ESD Control Products Since 1986

A Trusted UK Supplier Of ESD Control Products Since 1986

Before setting up your ESD workstation, you will firstly need to refer to the most up to date IEC61340-5 standard which will give you all of the information you will need to set up an ESD workstation safely and within the current specification.

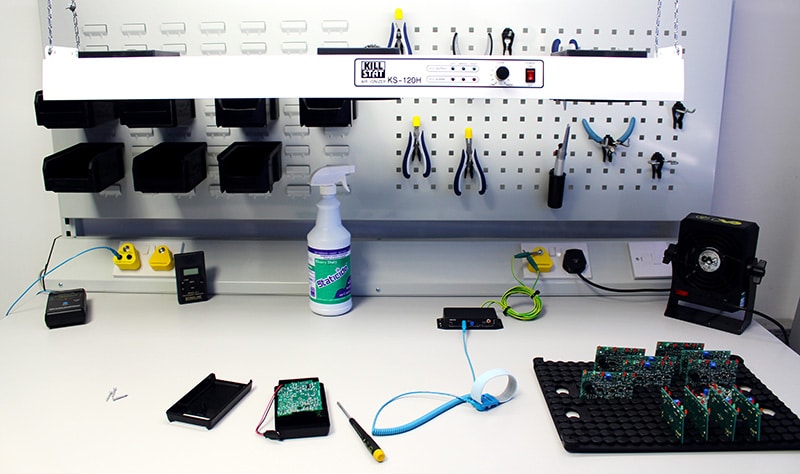

There are ESD protective workbenches, and selecting one would be the best practice. However, most companies use regular workbench. Materials used can vary, but it is best to use a workbench that is constructed of metal and wood, and not one containing large portions of high charging insulative plastic.

Most workstations will use pliable ESD matting to cover the bench and be the ESD work-surface on which to handle ESD sensitive (ESDS) items. The mat needs to be grounded and the best practice is to use metal grounding hardware snaps and ground cords connecting the work-surface mat to the common point ground. The entire bench-top should be covered by the ESD mat. Matting can be conductive or dissipative. Per ANSI/ESD S20.20 the required limit is less than 1 x 10E9 ohms and ANSI/ESD S4.1, the work-surface standard, recommends a low limit of 1 x 10E6 ohms. Per S4.1

A Working Surface Mat Grounding Cord and/or a Floor Mat Grounding Cord.

A basic ESD control rule is to ground all conductors including people at the ESD workstation. Grounding works great and will reliably remove ElectroStatic Charges to ground.

A Common Ground Point – An Earth Bonding Point (EBP) Plug or Bracket.

The first step in ensuring that everything in an EPA (ESD Protected Area) is at the same electrical potential is to ground all conductive components of the work area (work-surfaces, people, equipment, etc.) to the same electrical ground point. This point is called the common point ground. The next step in completing the ground circuit is to connect the common point ground to the equipment ground (third wire, green). Most locate the common point ground at the side edge of the workbench or towards the back of the bench-top.

Most workers, required for sitting workers, will be grounded via a wrist strap. The wrist strap needs to be selected and there needs to be an adequate number of ground points available. Even if typically the workstation is for only one worker, more than one ground point should be available to ground an additional worker, supervisor, or other ESD control element.

It is not required to have ESD flooring, but it could be selected to be low charging and/or a means to ground mobile equipment. Per S20.20, the required limit for Flooring is less than 1 x 10E9 ohms. For a standalone ESD workstation, a floor mat can be used with a ground cord connected to the workstation’s common point ground. We recommend conductive floor matting less than 1 x 10E6 ohms to be able to meet the Flooring/Footwear required limit of less than 3.5 x 10E7 ohms.

Instead of a wrist strap, a standing or mobile worker can be grounded using a Flooring/Footwear System. So ESD shoes or foot grounders can be selected. This means of personnel grounding requires both ESD flooring and ESD footwear. The ESD footwear is to be on both feet. Unless body voltage testing has been completed, the required limit per Compliance Verification ESD TR53 is of less than 3.5 x 10E7 ohms. The best practice is to use sole grounders or full coverage grounders and not heel grounders.

A bench-top ionizer or overhead ionizer can be selected to neutralize ElectroStatic charges at the workstation. This is the only ESD control method available to neutralize ElectroStatic charges on essential insulators or isolated conductors that may be at the workstation. The required limit per S20.20 is less than +/- 50 volts offset voltage (balance). In addition, the Discharge Times should be measured, both the time necessary to reduce +1,000 volts to +100 volts and the time necessary to reduce -1,000 volts to -100 volts.

ESD Bags, ESD Packaging, and ESD Storage.

Packaging and material handling containers at the ESD workstation should be low charging and have resistance (conductive or dissipative) so ElectroStatic charges can be removed to the ground. Shielding bags are also used additionally having the ESD control property of discharge shielding.

On selected products if ordered before 1pm

Dedicated account manager to help your ordering process

Great value on premium quality products