A Trusted UK Supplier Of ESD Control Products Since 1986

A Trusted UK Supplier Of ESD Control Products Since 1986

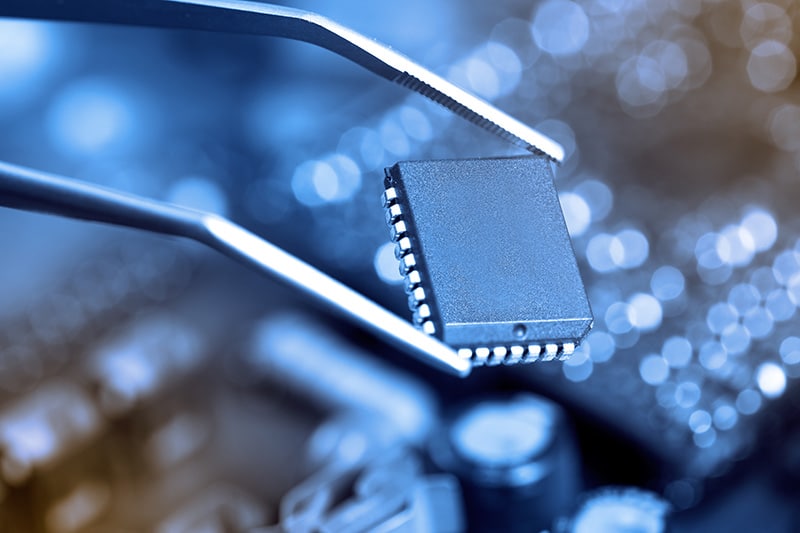

Bondline’s range of hand tools and tweezers are great for handling small electronic parts, such as PCBs, that require high-precision and careful handling. With our wide selection, finding the right tool couldn’t be any easier.

Purchase online today

Hand tools and tweezers couldn’t be any more vital in electronics manufacturing, whether that be for repairing components or assembling them. They play a significant role for those who are hobbyists, manufacturers, engineers, etc.

Anti-static tools are designed to be a part of a complete program to safely discharge static.

Static electricity naturally builds up through three different processes:

1) Tribocharging: Two materials (like socks and carpet) are brought into contact and then separated.

2) Electrostatic induction: An electrically charged object is placed near a conductive object that isn’t grounded.

3) Energetically charged particles impinge on an object: This is mostly a problem for spacecraft.

The most effective prevention for static electricity isn’t so much a single tool, as it is a system of precautions, grounding mechanisms and a lack of highly charged materials. Together, this creates an Electrostatic Discharge Protection Area (EPA) that works to keep electrostatic discharge (ESD) sensitive materials safe.

The principles of a successful EPA include:

1) No highly charged materials.

2) All conductive materials are grounded.

3) Workers are grounded.

4) Electrostatic charge builds up on ESD-sensitive electronics is prevented

The hand tools you use in this environment are often made from plastics that are specifically created to work within this delicately balanced system. These electrostatic dissipative (ESD) tools have a balanced charge and low surface resistivity, which means they don’t gain or lose charge to the objects and surfaces that surround them. These tools have precise temperature and humidity ranges that they work in. If they’re used outside those ranges, they may still create a static charge.

Precision modern electronics require sensitive handling and semiconductors, wafers, memory chips, processor units and hard drives are just some of the items which require protection from static electricity. This range of critical ESD workplace tools are all insulated and designed to mitigate the effects of static, helping to protect your working environment. Accessories such as ESD pliers, cutters and tweezers will ensure that a technician is properly grounded before commencing work on a static-sensitive device.

By taking environmental precautions, using grounding straps and investing in ESD-safe tools, you’ll be able to control and prevent ESD damage while working on PC repairs, smartphones, making circuits, and many more projects. By taking extra steps like these, you’ll save time and money preventing and diagnosing problems down the line. ESD-safe tools are an affordable solution to help you in your work and they help keep your electronics safe!

When selecting a hand tool, you should choose one that is of a good quality. This is so the hand tool has a long longevity, meaning you wouldn’t have to spend money in replacing it any time soon. One way to identify a good quality hand tool is by looking at its materials and seeing whether the supplier is reputable. Once you have your hand tool, you should ensure that you take care of it properly.

Regarding Electrostatic Discharge (ESD), you should only use metal hand tools with static dissipative handles and never hand tools with handles made from highly-insulting materials such as rubber. Hand tools with static dissipative handles drain the static charge in a slow and controlled manner. In other words, this means that if you are charged for some reason (i.e. not wearing a strap) and you pick the tool up and touch it to a component, the charge will equalise slowly and not damage the component rather than quickly with a spark which would damage the component.

If you’re looking for ergonomic ESD hand tools, Bondline’s hand tools are manufactured to the very highest standards.

Ideal-tek high-precision cutters combine superior cutting quality and durability with unique design and ergonomics, resulting from careful attention to detail at every stage of the manufacturing process.

The increased usability depends on the non-slip rubber handle surface, which provides the operator with a better grip and a more pleasant feeling. The Bi-component ergonomic handles with rounded surface support a more natural thumb position, offering superior comfort during production and repair of electronic devices.

High quality ball bearing steel, double-leaf stainless steel springs, hardened alloy steel nuts, perfect symmetry and fine-pitched screw ensure perfect joint adjustment and exceptional cutting performance. ESD-safe high-precision cutters offer maximum comfort, reliability and precision in the manufacture and repair of electronic devices.

Multi-purpose hand tools with opposing jaws, pliers are essential for gripping, bending, adjusting and straightening wires and different materials. Ergo-tek High Precision Pliers feature ergonomic handles with a soft gripping surface that increases comfort and safety during the production and repair of electronic devices.

The ESD-safe Bi-component grips provide the operator with a safer seize and a more pleasant feeling, while the rounded ergonomic profile offers maximum comfort during each operation. Despite their great adaptability to different tasks, the pliers are manufactured to different specifications to meet defined tasks with greater safety and efficiency.

The Ergo-tek Slim line completes the range of high precision pliers with a set of lighter and slimmer precision instruments recommended for small hands during the production or repair of electronic devices.

Piergiacomi has become the leader in its field in the manufacture of hand tools, in shearing, in electronics and in parts, in the electro-technical field. No other manufacturer has a range of tools as wide as Piergiacomi: more than 400 different types of tools, well known and sought after by the industrial electronics market worldwide under the name of “Piergiacomi Quality Hand tools”.

Bondline’s anti-magnetic tweezers are available in a range of lengths and point types. These are designed for use in the electronics industry where static sensitive components and devices are handled. They are high-quality precision instruments produced using a non-magnetic stainless steel alloy.

Can’t find what you are looking for? Please contact one of our expert sales members for more advice

On selected products if ordered before 1pm

Dedicated account manager to help your ordering process

Great value on premium quality products

Bondline Electronics uses cookies and tracking technologies to analyse our traffic, and for advertising/targeting purposes.

Cookie technology helps us to deliver content tailored to a visitor's interest, improve our site's performance and security, and makes a number of actions easier.

You can read more in our Privacy Policy and find out how to opt out at any time.